What are Base Oils?

Base oils are the starting material for producing lubricants, and their properties greatly influence the performance and characteristics of the finished lubricant. They are typically derived from crude oil but can also be made from synthetic or bio-based sources. The American Petroleum Institute classifies them into five base oil groups.

Base oils define the inherent properties of the finished product, including viscosity, stability/longevity, and load-bearing capacity (the ability to withstand extreme pressures).

For example, a lubricant made with a high-quality, highly refined base oil may have better thermal and oxidative stability than a lubricant made with a lower-quality base oil but NOT have the same degree of load-bearing capacity as a result of the molecular structure and purity.

As a result, the choice of base oil is an essential consideration in producing lubricants. Consequently, selection requires careful thinking and planning around the machine’s operating conditions to produce a finished product that serves the long-term performance interests of the machine owner.

Base Oil Categories

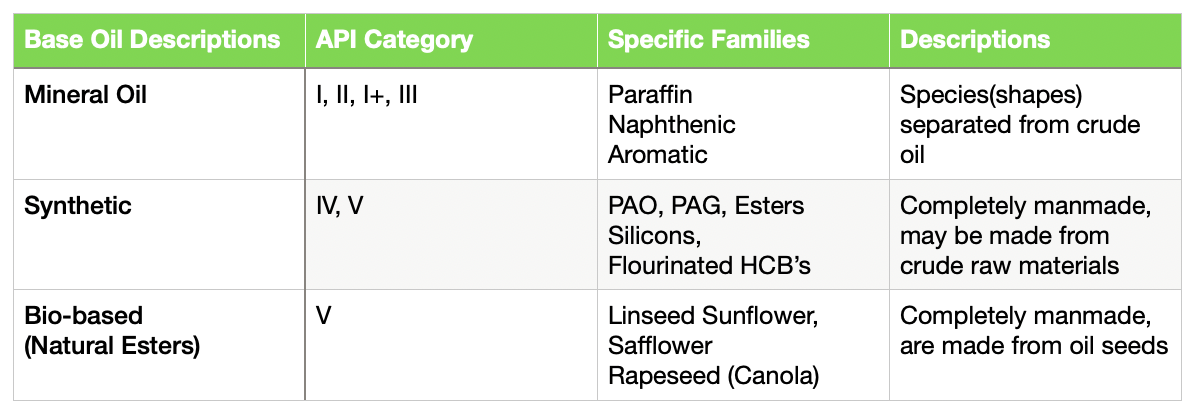

The three general categories of base oils are mineral, synthetic, and bio-based. Beyond these categories, there are well-defined and accepted technical categories that lubricant manufacturers use to select base oils.

Mineral base oils are derived from crude oil and are the most commonly used type. They are relatively inexpensive and widely available but also have some limitations, such as a relatively low viscosity index and poor thermal stability.

Mineral base oils are classified according to their refining process and viscosity, such as paraffinic, naphthenic, or aromatic.

Synthetic base oils are man-made and can be tailored to have specific properties, such as a high viscosity index or superior thermal stability. They are typically more expensive than mineral, but they can improve machine performance in many applications.

Synthetic base oils are classified according to their chemical structure, such as PAOs (polyalpha olefin), PAGs (poly alkaline glycol), or esters (diester, polyol ester, phosphate ester, etc.).

Bio-based are derived from renewable sources like vegetable oils or animal fats. They may have similar properties to mineral base oils but are more biodegradable and environmentally friendly.

Bio-based base oils are typically classified according to their feedstock, such as vegetable oil-based or animal fat-based. Like synthetic base stocks, bio-based materials are considered entirely man-made (synthesized) and are expected to demand a higher price.

Advantages and Disadvantages

The advantages and disadvantages of each base oil type depend on the lubricant’s specific application and performance requirements. Mineral oils have the advantage of being widely available and less expensive, but they might have limited performance in particular applications.

Synthetics have the advantage of being tailored to have specific properties, but they may be less compatible with certain additives or seal materials.

Bio-based have the advantage of being environmentally friendly and biodegradable, but are more expensive (than mineral oils) and have somewhat limited availability.

The fundamental base oil properties important in producing lubricants include viscosity, viscosity index, pour point, flash point, and thermal stability. These properties determine how well it will maintain its flow characteristics at different temperatures, how well it will resist oxidation and breakdown, and how well it will protect against wear and friction.

The specific properties of each type will vary depending on its source and refining process.

Base Oil Production and Refining

The process of extracting base oils from crude oil involves several steps, including crude oil selection and preparation, distillation, and refining.

First, the crude oil is selected and prepared for refining by removing impurities such as water, sediment, and other contaminants. The crude oil is then heated and distilled to separate into different fractions based on their boiling point. The lighter fractions are used to make gasoline and other fuels, and the heavier fractions are used to make base oils.

The heavy fractions of crude oil used to make base oils are called lubricating oil stocks, and they typically have a high viscosity and a complex chemical structure. These lubricating oil stocks are then refined to produce finished base oils. The refining process may involve several steps, such as solvent refining, hydrocracking, or iso-dewaxing, to remove impurities, improve the chemical structure, and improve the performance properties of the base oil.

After refining, the base stocks are packaged and shipped to lubricant blenders (manufacturers), where base stocks are mixed with additive blends to produce finished lubricants.

The refining process and the additives used can vary depending on the type of base oil and the desired properties of the finished lubricant.

This piece is from ” Base Oil:An in-depth Look“ from “Precision Lubrication “

For full article: https://precisionlubrication.com/articles/base-oils/